Продукция

Peristaltic pumps

Application

Peristaltic pumps of NP series are self-priming pumps and are used for pumping chemically active and neutral liquids with viscosity up to 4500 centipoises (4.5 Pа/s) and density up to 3000 kg/m3 (depending on pump size, pump rotor speed and pump inlet absolute pressure). Pump body is partially filled with glycerin for cooling and lubrication of hose that helps to increase its operating life.

Principles of operation

For principle of action pumps are related to machines of high-volume action.

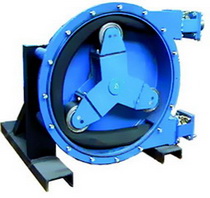

The action of peristaltic hose pump is based on interchange between compression and decompression of working hose form. Special construction hose (pic.1) is installed inside of the body (pic.2). During rotation the rollers pinch the hose, providing content pumping and its movement inside of the hose. Reverting into hose form original position after roller, creates almost complete vacuum, causing pumping of the content.

|

|

|

| Picture 1 | Picture 2 |

Advantages of the pump

- Volume of the pumped fluid per one turn remains constant, which allows using pumps as a measuring device.

- Pumped fluid contact only with inner walls of the hose that allows using pumps for pumping aggressive media, food and other solutions, which contact with working parts of the pump must be prevented.

- During pumping the structure of the media remains the same that is most important in many cases when choosing the pump.

- It is allowed to pump media with high viscosity with a maximum working pressure up to 1.5 MPa.

- Presence of abrasive solid particles is tolerable; size of such inclusions can be up to 10% from the inner diameter of the working host (15% for single particles). Solid particles concentration in pumped media is limited only by requirements of viscosity, density and flowability.

- Pumps can transfer gas-liquid mixtures.

- Pumping of crystallization-prone media is allowed due to absence of valves and membranes with possibility of deposit formation.

- Pumps can work in dry mode (without transferring media).

- Explosion proof (no dry friction between metal parts).

- Self-priming (due to vacuum formation pump can suck transferring media).

- Pumping media temperature can be from +5оС to +110оС (depending on working hose type).

- Reliability and easy maintenance (hose is the only wear-prone part), so the breakdown time is minimal.

Pump's field of application

Due to the construction these pumps can be used in different fields, where pumping of specific media are needed (Table № 1).

Table 1

| Media properties | Field of application | Place of application | Remarks |

|---|---|---|---|

| High viscous media | Paint and coatings industry; petroleum industry; rescue and environmental services | Pumping of lacquers, paints and filling colour; oil sludge; oil and mud gathering | Viscosity max to 4.5 PA/s |

| Abrasive media | Building industry | Building mixtures; foamed concrete, polystyrene concrete | Abrasive content max to 80% from total media volume |

| Media with foreign inclusions |

Metal industry; mining industry; cellulose and paper industry; wastewater treatment facilities |

Water with content of shruff and sludge; pulp and paper industry wastes; wastewater | Solid inclusions with diameter to 10 mm |

| Chemically active media * | Chemical industry | Transferring of acids, alkalis, chemically aggressive media | Chemically stable performance |

| Food ingredients | Food industry | Transferring of oil, grease, ketchup, chocolate, molasses | Hose construction for food industry |

| Explosive solutions * | Explosive works | Transferring of explosive components | Explosive media contacts only with hose |

| Medications, solutions | Pharmacology, medicine | Solutions and medicaments dosage | Hose construction for pharmacology |

* except for nitric acid and compounds which in contact with glycerol may form explosive, flammable or toxic material. In this case, use different cooling mixture or operate pump without it.

Technical characteristics

Technical parameters of peristaltic pumps during operation on water basis under temperature up to +30оС are shown in table № 2.

Table №2

| Pump type | Productivity, m3/hour | Pressure (max), MPa | Pumping distance, m | Pumping head, m | Rotor speed, rev/min | Capacity, kW | Length, width, height, mm | Weight, kg |

|---|---|---|---|---|---|---|---|---|

| NP-25-1,5/56* | 0,9 | 1,6 | 45 | 25 | 56 | 1,5 | 800х750х600 | 180 |

| NP-40-2,2/35,5 | 2,1 | 1,6 | 60 | 30 | 35,5 | 2,2 | 900х800х700 | 200 |

| NP-40-3/56* | 3,4 | 1,6 | 60 | 30 | 56 | 3 | 900х800х700 | 230 |

| NP-40-3/71* | 4,3 | 1,2 | 60 | 30 | 71 | 3 | 900х800х700 | 230 |

| NP-50-4/45 | 4,7 | 1,6 | 60 | 30 | 45 | 4 | 1000х800х750 | 300 |

| NP-50-5,5/45 | 4,7 | 1,6 | 60 | 30 | 45 | 5,5 | 1000х800х750 | 300 |

| NP-50-5,5/56* | 5,9 | 1,2 | 60 | 30 | 56 | 5,5 | 1000х800х750 | 320 |

| NP-50-5,5/71* | 7,5 | 1,2 | 60 | 30 | 71 | 5,5 | 1000х800х750 | 320 |

| NP-50-7,5/56* | 5,9 | 1,0 | 60 | 30 | 56 | 7,5 | 1000х800х750 | 320 |

| NP-50-7,5/71* | 7,5 | 1,0 | 60 | 30 | 71 | 7,5 | 1000х800х750 | 320 |

| NP-65-5,5/45 | 10,8 | 1,5 | 60 | 30 | 45 | 5,5 | 1115х900х920 | 400 |

| NP-65-7,5/45 | 10,8 | 1,5 | 60 | 30 | 45 | 7,5 | 1115х900х920 | 420 |

* pump operation mode is cyclic for cooling hose and body.

** indicated parameters in table 2 are referential and are given for operation on water basis. Distance and head of pumping for transferring other media are determined after order of the pump, and depend on density and viscosity of the particular media.

Depending on the type of transferring media and operation environment, pumps are equipped (pic.3) with hose of certain parameters: abrasion resistant, acid-proof, for food transferring etc. There are many variants of construction:

- impellers with two or three rollers;

- inlet and outlet pipes: carbon or stainless steel;

- different types of connection of inlet and delivery pipes: union pipe, camlock and others.

For right choice of hose modification and pipes material, it is important to indicate the type of pumping media, its concentration and temperature in order list!

Pumps can be equipped with electric motor in common industrial (О) or explosion proof (В) versions for different operating conditions.

Pumps can be equipped with additional parts.

Frequency controller:

- allows smoothly adjust rotor speed;

- connects pump with automatic system of monitoring and control.

Pulsation damper:

- smooth pulsation in pump outlet.

Pressure monitor:

- allows to control pressure in pump outlet.

Suction hose (reinforced with steel or plastic spiral):

- designed for connection of pump with inlet pipe.

Hose pressure head (depending on the pumped media, abrasive, chemically resistant, etc.):

- designed to connect pump with delivery pipe.

Peristaltic pump with a frequency regulator

Pouring floors

Peristaltic pump NP-50 with compensator

A compensator is needed for smoothing the pulsations from the pump outlet.

Peristaltic pump NP-50 with compensator

Peristaltic pump NP-50

Peristaltic pump NP-50 with frequency converter and a compensator for a smoothing of pulsations.