Продукция

Equipment for foam concrete production

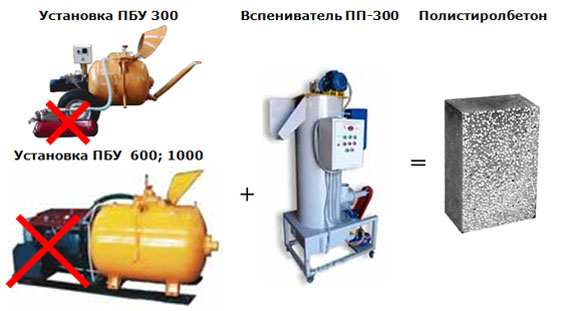

Equipment for foam concrete are designed for production of foam concrete through forced mixing of foam with solution and further pumping of prepared foam concrete to the placing point (formwork; shuttering etc.). Foam is operated by pneumatic generator. Equipment for foam concrete production is also used for preparation of polystyrene concrete and foam polystyrene concrete.

Mobile foam concrete facility ПБУ-300

Application places: production of foam concrete particularly on building sites territory, filling the shuttering, production of foam concrete blocks using formworks.

| Prepared solution volume, L | 270 |

| Productivity, m3/hour | 1,5-3 |

| Metric volume, m3 | 0,3 |

| Pressure, MPa | up to 0,7 |

| Air output, m3/min | from 1,0* |

| Capacity, kW | 2,2; 3,0 |

| Fraction size, mm | up to 30* |

| Mortar pipeline diameter, mm | from 50* |

| Voltage/frequency, V/Hz | 220/50; 380/50 |

| Outline dimensions, mm | 2300х1100х1100 |

| Weight without mortar pipeline, kg | 600 |

Advantages:

- mobility;

- reliable operation;

- easy maintenance and operation;

- foam generator made of stainless steel;

- prepare and pump solutions with density up to 1800 kg/m3.

Mixer is installed on chassis. This equipment is mainly used on building sites, provided with electricity and water. For successful operation you need to obtain compressor with productivity from 0.5 m3/minute.

| ПБУ-300 | FOAM GENERATOR | FOAM CONCRETE | ||

|

+ |

|

= |

|

Foam concrete facilities ПБУ-600, ПБУ-1000

Application places: Foam concrete facilities are used for production of foam concrete construction blocks and heat insulation blocks using formworks.

| Prepared solution volume, L | 540; 900 |

| Productivity, m3/hour | 3-5 |

| Metric volume, m3 | 0,3 |

| Pressure, MPa | up to 0,7 |

| Air output, m3/min | from 2,0* |

| Capacity, kW | 5,5; 7,5 |

| Fraction size, mm | up to 30* |

| Mortar pipeline diameter, mm | from 65* |

| Voltage/frequency, V/Hz | 380/50 |

| Outline dimensions, mm | 3000х1100х1300 |

| Weight without mortar pipeline, kg | 1200, 1450 |

Advantages:

- reliable operation;

- easy maintenance and operation;

- foam generator made of stainless steel;

- especially effective during mechanical loading (extra performance);

- prepare and pump solutions with density up to 1600 kg/m3.

Mixer is installed on ring-bridge structure. This equipment is mainly used on building sites, provided with electricity and water. For successful operation you need to obtain compressor with productivity from 0.5 m3/minute.

Polystyrene concrete production installation on the basis of foam concrete equipment

Production of polystyrene concrete doesn’t have essential differences from foam concrete production. The only difference is the need to purchase polystyrene foam granules or its own production with foaming machine, which is more profitable during significant production volumes. In addition to this there is no need for foam generator.

When using special foaming machine you can produce foam polystyrene concrete. Foaming is the process of mixing of solution with polystyrene.

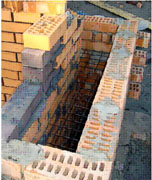

Filling polystyrene concrete or foam polystyrene concrete into shuttering has most economical benefit. That considerably reduces filling time, supporting structures weight, materials and work expenses, and what is most important is the achievement of better heat and sound isolation comparing with other materials.

Also using filling formworks you can produce blocks. Such blocks made of polystyrene concrete are lighter and stronger that foam concrete ones, moreover they are less likely to cause shrinkage cracks.

|

|

|

| Before filling | Filling with polystyrene concrete | After filling |

Foam generator ПП-250

Foam generators are designed for foam preparation used in foam concrete production.

Foam productivity and frequency can be controlled and regulated by valves.

This generator is light, mobile, has easy maintenance and operation.

| Productivity, L/hour | 250 |

| Air output, m3/min | 0,1-0,15 |

| Tank capacity, L | 50 - 100 |

| Weight, kg | 25 |

Block mould ФПБ-18/200, 27/100

Block moulds are used for production of foam concrete and polystyrene concrete blocks. Block mould is light, easy disassembled, keeps warm.

| Block size, mm | 600х300х200, 600х300х100 |

| Quantity of blocks | 18 units, 27 units |

| Mould material | Moisture resistant laminwood |

Foaming agent

Foaming agent is designed for foam preparation, used in foam concrete production.

| 1 kg of foaming agent consumption rate | 4-6 m3 of foam concrete |

| Packing (plastic barrel) | 200 kg |

| Consistence | Concentrated gel |

| Consumption rate per 1 m3 of foam concrete, kg | 0,7 |

| Manufacturer | Germany |

Advantages:

- good foaming;

- low consumption rate;

- environmentally safe;

- long shelf life.

Our specialists conduct installation and start-up work on building sites of the customer, as well as provide training of staff for successful operation.